Laser power(w): 1500~6000W

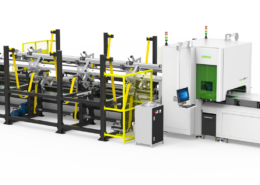

Songu Laser Technology’s Tube series 2-chuck loading tube laser cutter, the machine tool adopts a large gantry machining center for precision machining: through a large-scale gas-heated combined car heat treatment furnace, equipped with pneumatic self-centering chuck, the equipment has a power failure memory function, professional nesting software and laser cutting system are highly integrated, with unique functions and cutting effects. Application: carbon steel pipe laser cutting, stainless steel pipe laser cutting.

Features

Intergrated multi-functions into one, create more value for customer

Multiple protection functions

The equipment enjoy power failure memory; retreat cutting; automatic fault alarm and emergency stop; fault info auto-display;

Professional software

Software can help to Auto Find Tube Center in Production, and enjoy Active Control at Corner Cutting;

High precision

Support offset tube center error in production to improve through holes cutting precision. Beside standard tube like square and round tube, TubePro also supports profiles and free form tube production of U/L/H/T channels, Obround oval and polygon etc;

High precision and stability

Machine bed: large gantry milling, 600℃ heat treatment , 24 hours cooling inside the furnace to ensure the steel welded then guarantee the machine tool long term accuracy and stability; cutting; automatic fault alarm and emergency stop; fault info auto-display.

Specification

Optimization and innovation, make product faster, more stable, more assured.

| Model | TUBE7524A |

|---|---|

| Working area | Round pipe ≤ φ 360, □ 20 ≤ square pipe ≤ □ 360, rectangular pipe ≤ 350×250, channel steel ≤ 36 #, I-steel ≤ 36# |

| Laser power | 1500~6000W |

| Max. blanking length | 0-2000mm |

| Max. load of chuck | 260kg |

| Automatic feeding length | 6000mm |

| Equipment weight | 4500kg |

| Max. blanking length | 0-2000mm |

Application

Mainly used for round pipe, square pipe, rectangular pipe, oval pipe and other kinds of pipe laser cutting.

Product Video

Every detail strives for perfection, with humanized operation desks, all-round design, and stainless steel edging, to create industrial products with luxury requirements to meet your needs for product appearance and taste.

Related Model

Opening a new era of laser intelligence