Laser power(w): 1500~6000W

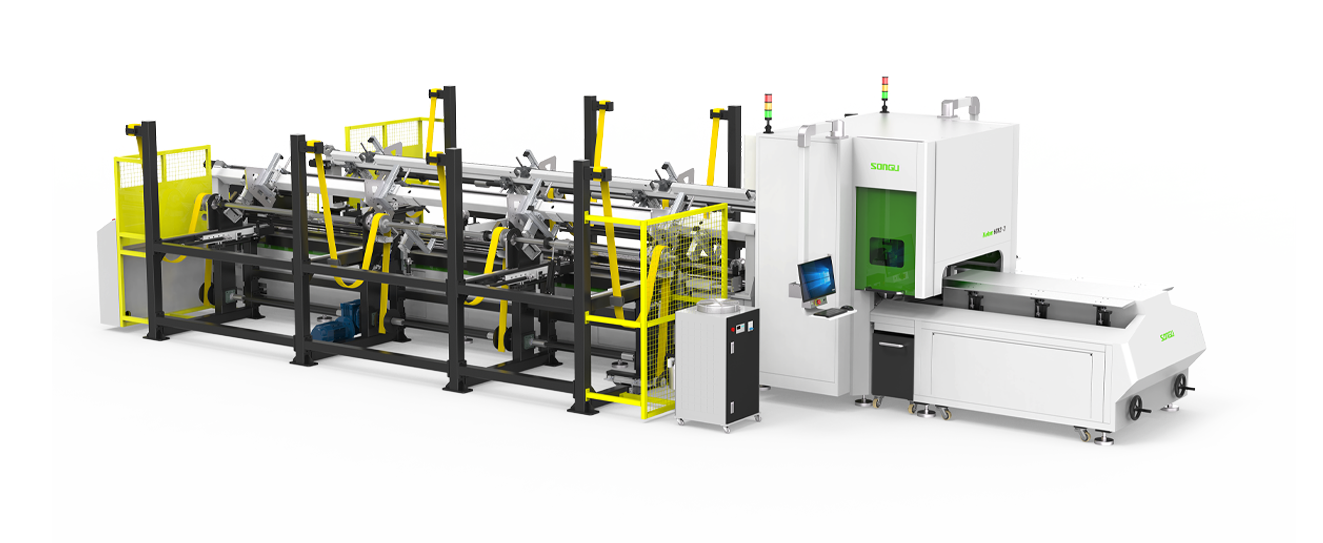

Songu Laser Technology’s Tube Series 2 in 1 Tube Fiber Laser Cutting for Small Tube Machine integrates 2 tube cutting system in 1 body, both heads could work separately; integrated design of feeding, receiving and cutting mechanism; Suitable for carbon steel pipe laser cutting, SS pipe laser cutting.

Features

Intergrated multi-functions into one, create more value for customer

Double the cutting efficiency

Integrates 2 tube cutting system in 1 body, both head could work separately, very compact design also enjoy double productivity;

Multiple protection functions

The equipment enjoy power failure memory; retreat cutting; automatic fault alarm and emergency stop; fault info auto-display;

Integrated design

Integrated design of feeding, receiving and cutting mechanism, effectively reducing the floor space;

Pneumatic self-centering chuck

Equipped with a pneumatic self-centering chuck, some types of pipes can be cut and processed with almost zero tailing, fully improving the utilization rate of pipes;

High accuracy and stability

Machine tool: large gantry milling, 600°C heat treatment, 24 hours cooling inside the furnace to ensure the steel welded joint stress relief;

Professional software and system

Support offset tube center error in production to improve through holes cutting precision. Besides standard tube like square and round tube.

Specification

Optimization and innovation, make product faster, more stable, more assured.

| Model | Tube6524A |

|---|---|

| Working area | φ15≤ round pipe ≤φ240, □15≤ square pipe ≤□240, rectangular pipe ≤230×140, channel steel ≤22#, I-steel ≤22# |

| Claw clamping weight | 80kg |

| Laser power | 1500~6000W |

| Positioning accuracy | ±0.03mm/m |

| Maximum accelerated | 1.2G |

| Maximum moving speed | 120rpm/min |

| Weight | 4500Kg |

| Overall dimension | 11350×4400×2450mm |

Application

Mainly used for round pipe, square pipe, rectangular pipe, oval pipe and other kinds of pipe laser cutting.

Product Video

Every detail strives for perfection, with humanized operation desks, all-round design, and stainless steel edging, to create industrial products with luxury requirements to meet your needs for product appearance and taste.

Related Model

Opening a new era of laser intelligence